Why are more construction professionals choosing post tension slabs over traditional concrete methods?

Many builders face the frustrating challenge of creating large open spaces while dealing with structural limitations, excessive material costs, and lengthy construction timelines that hurt project profitability.

Post tension concrete solves these problems by allowing longer spans with reduced thickness, excellent crack resistance, and faster construction timelines.

These specialized structures work by tensioning steel cables after concrete cures, creating superior performance compared to traditional methods.

This article covers tensioned concrete systems from basic definitions to cost analysis. Learn how to identify these systems, understand their advantages and disadvantages, and determine when they’re right for your construction project.

What is a Post Tension Slab?

A post tension slab is a concrete structure where steel cables are tensioned after the concrete has been poured and cured.

This construction method creates stronger, thinner slabs that can span longer distances than traditional concrete slabs. Post tension concrete is widely used in commercial buildings, residential construction, and parking structures.

The key difference from traditional slabs is that steel cables are tensioned after the concrete sets. This allows for thinner slabs while maintaining the same load capacity and better crack resistance.

These structures are ideal for creating open floor plans without numerous support columns, making them perfect for modern architectural designs.

How Thick Should a Tensioned Concrete Floor Be?

Post tension slab thickness typically ranges from 6 to 12 inches, depending on the application and load requirements.

Common thickness by application:

- Residential: 6-8 inches for typical household loads

- Commercial: 8-10 inches for office and retail spaces

- Heavy-duty: 10-12 inches for warehouses and parking structures

Thickness depends on several factors, including total load requirements, span distance between columns, soil conditions, and local building codes. Engineers can optimize thickness by adjusting cable spacing and tension levels to meet specific project needs.

Pro tip: Professional engineering analysis is required for proper thickness selection based on soil reports, load calculations, and local codes.

Key Considerations for Tensioned Foundation Slabs

Post-tension foundation systems apply tensioning principles specifically to foundation slabs, providing superior performance in challenging soil conditions.

- Best for challenging soils: Ideal for expansive clay soils, poor bearing capacity areas, and sites with significant ground movement.

- How it works: Tensioned cables create a continuous compression force, helping the foundation act as a single unit to prevent differential settlement.

- Design requirements: Proper soil analysis is essential, cable layout must account for soil movement patterns, and adequate edge distance for anchorages is needed.

- Maintenance needs: Regular inspection of exposed anchorages, monitoring for cable corrosion, professional assessment every 5-10 years.

- Failure warning signs: Floor or wall cracks, doors/windows that stick, gaps around baseboards, visible slab heaving or settlement.

- When to use: Areas where traditional foundations have failed, regions with known soil movement issues, sites requiring superior foundation performance.

The Post-Tensioning Working Mechanism

The working mechanism of post-tension slabs follows these key steps:

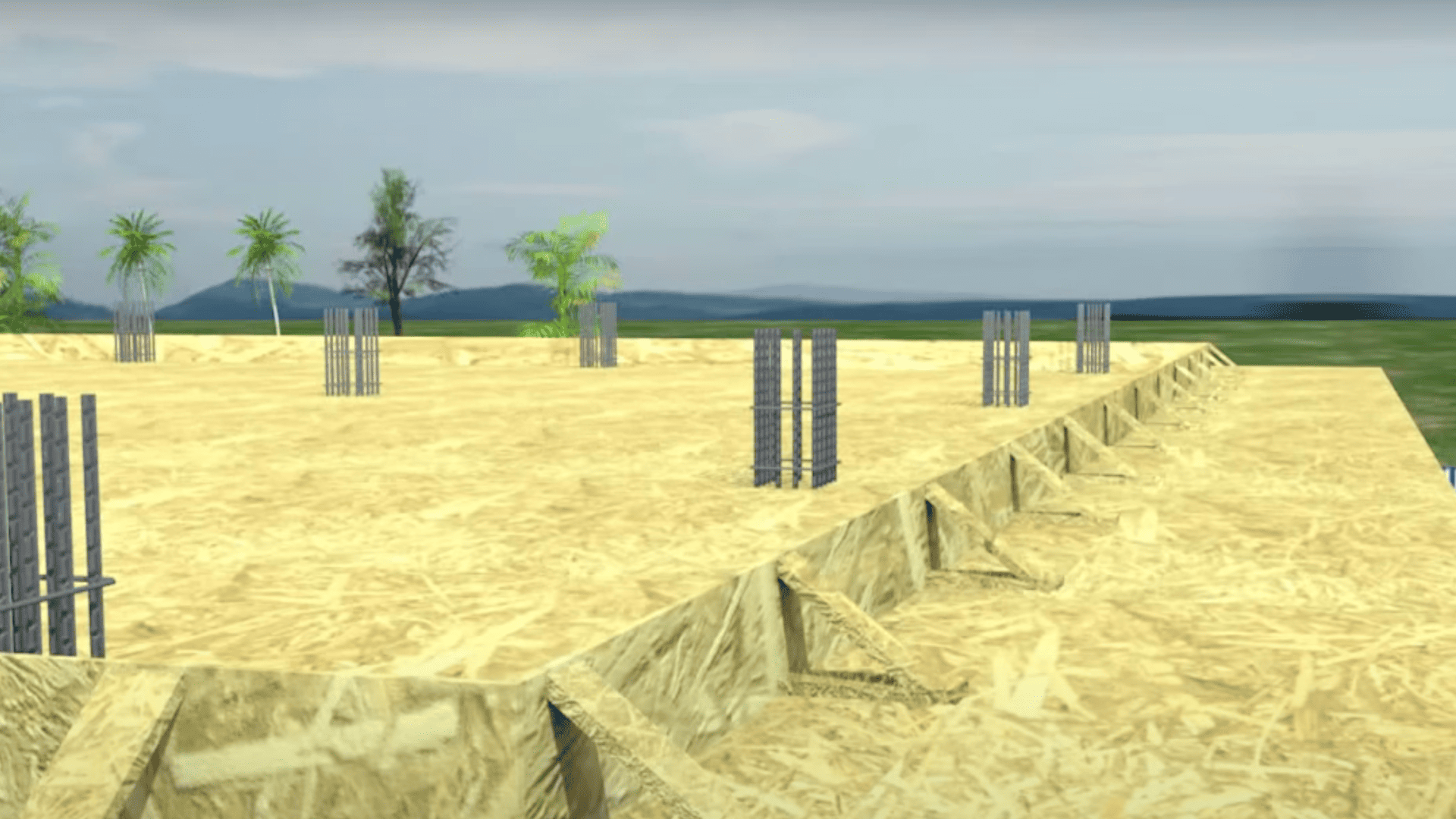

1. Formwork Installation

Set up both the base slab formwork and vertical side formwork systems.

The base formwork supports the concrete during pouring and curing, while side formwork contains the concrete and defines clean slab edges with proper dimensions.

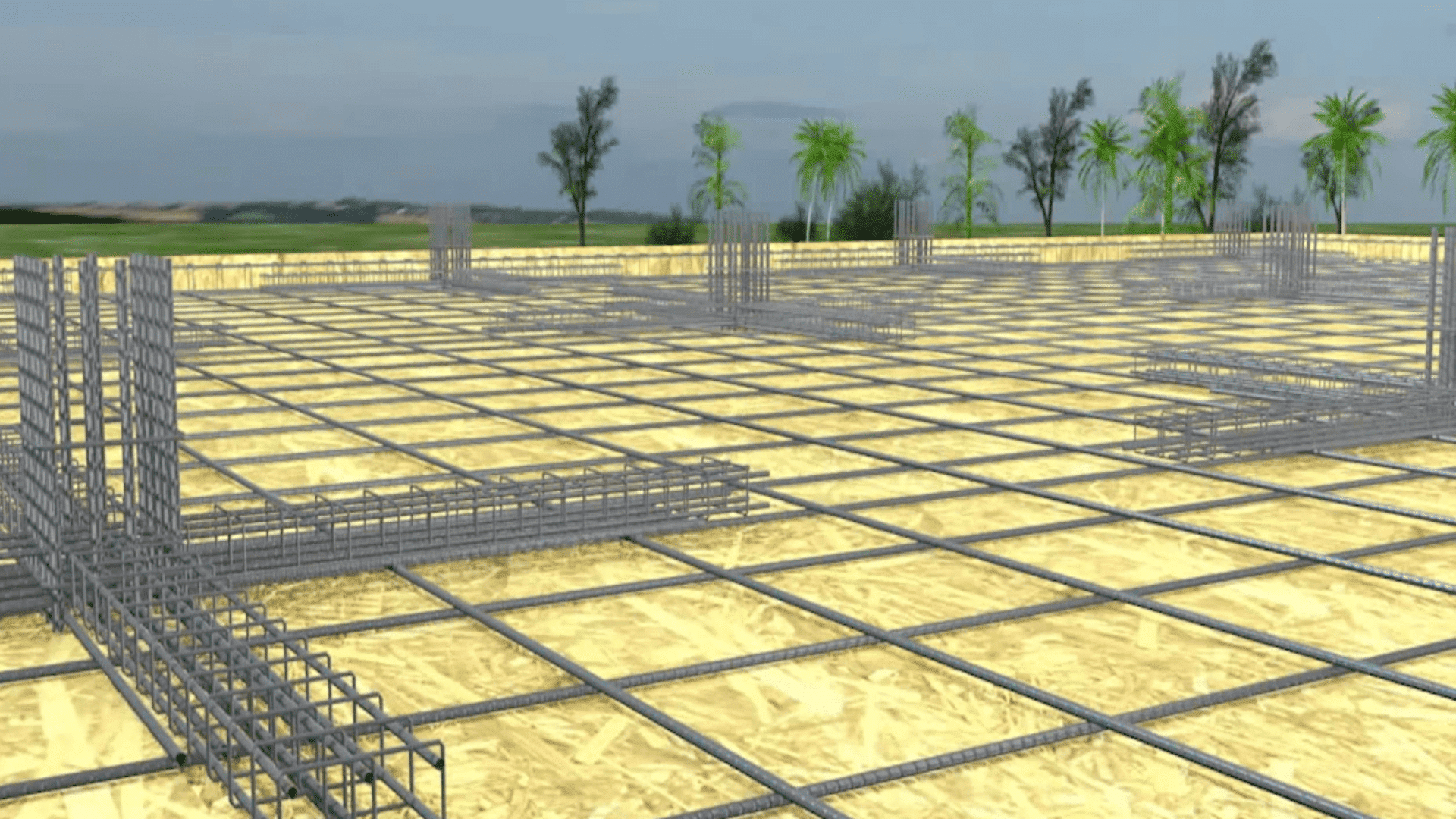

2. Reinforcement Placement

Install multiple layers of steel reinforcement, including lower reinforcement bars, anti-bursting reinforcement around anchor points, column reinforcement, and punching shear reinforcement.

Position all reinforcement according to structural design profiles and height requirements for optimal load distribution.

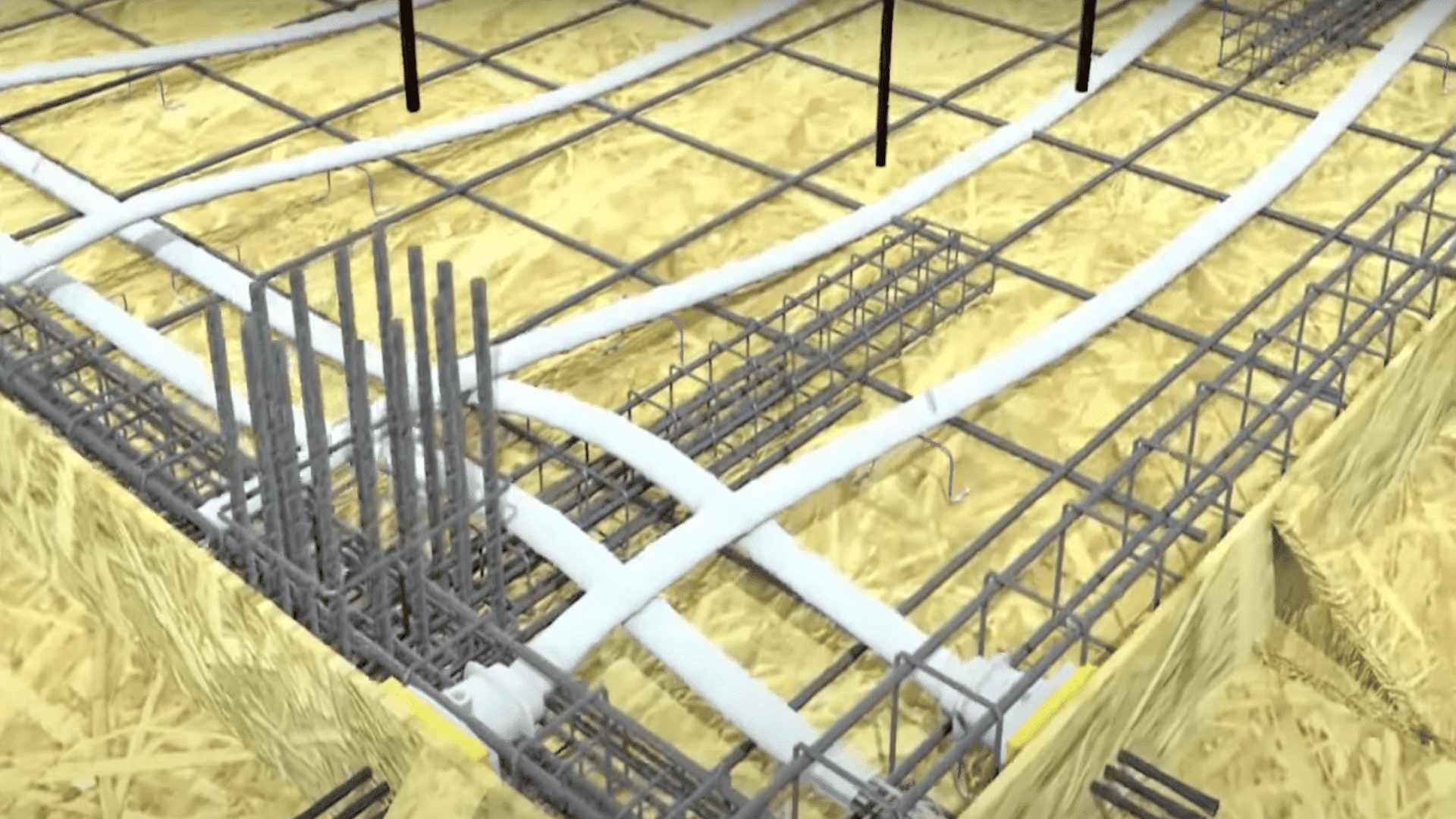

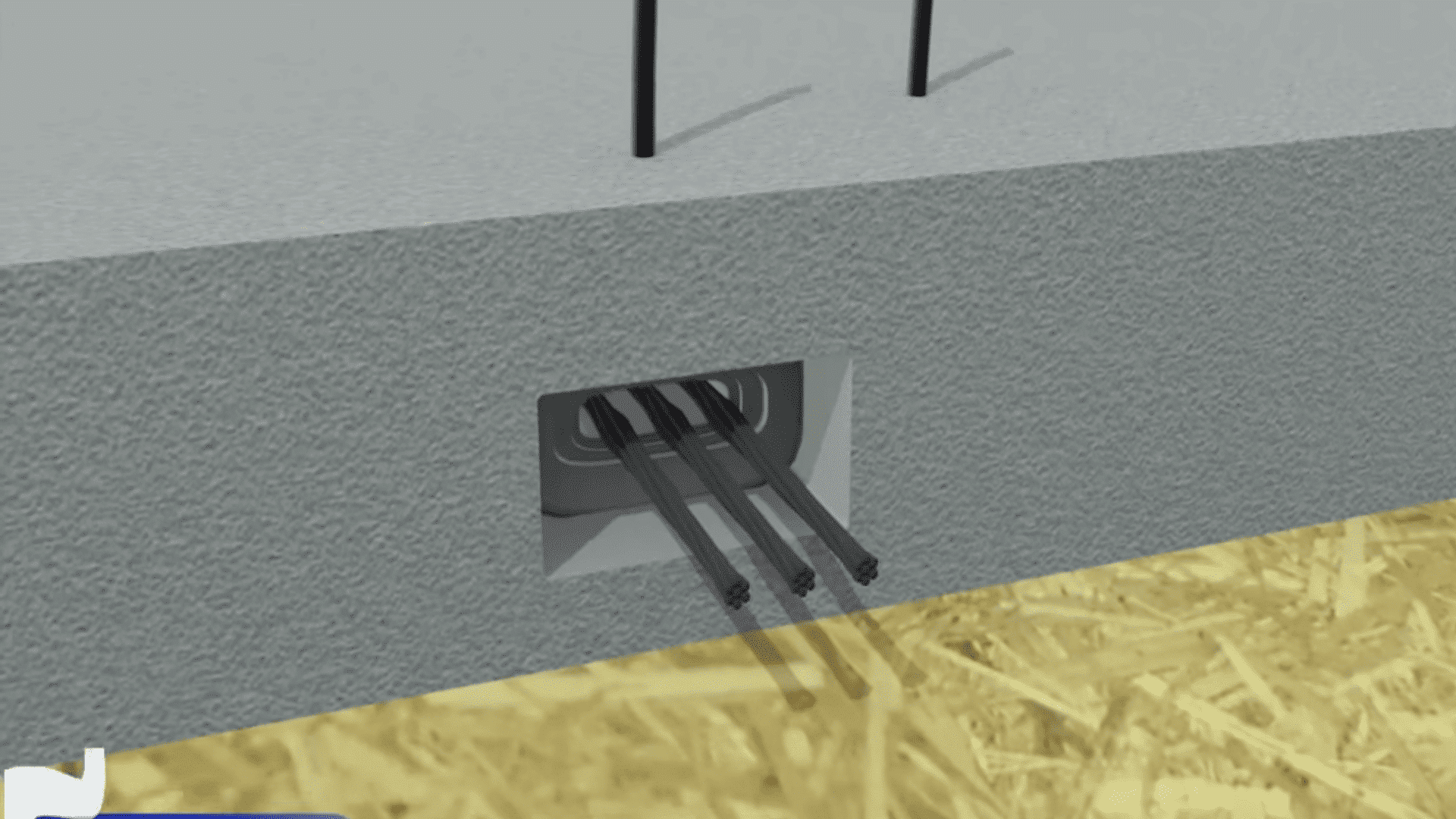

3. Tendon and Anchor Installation

Place the post-tensioning cables (tendons) and secure them to the reinforcement system according to design specifications.

Install anchorage systems at cable ends along with grout vents that will enable proper tensioning operations and long-term cable protection.

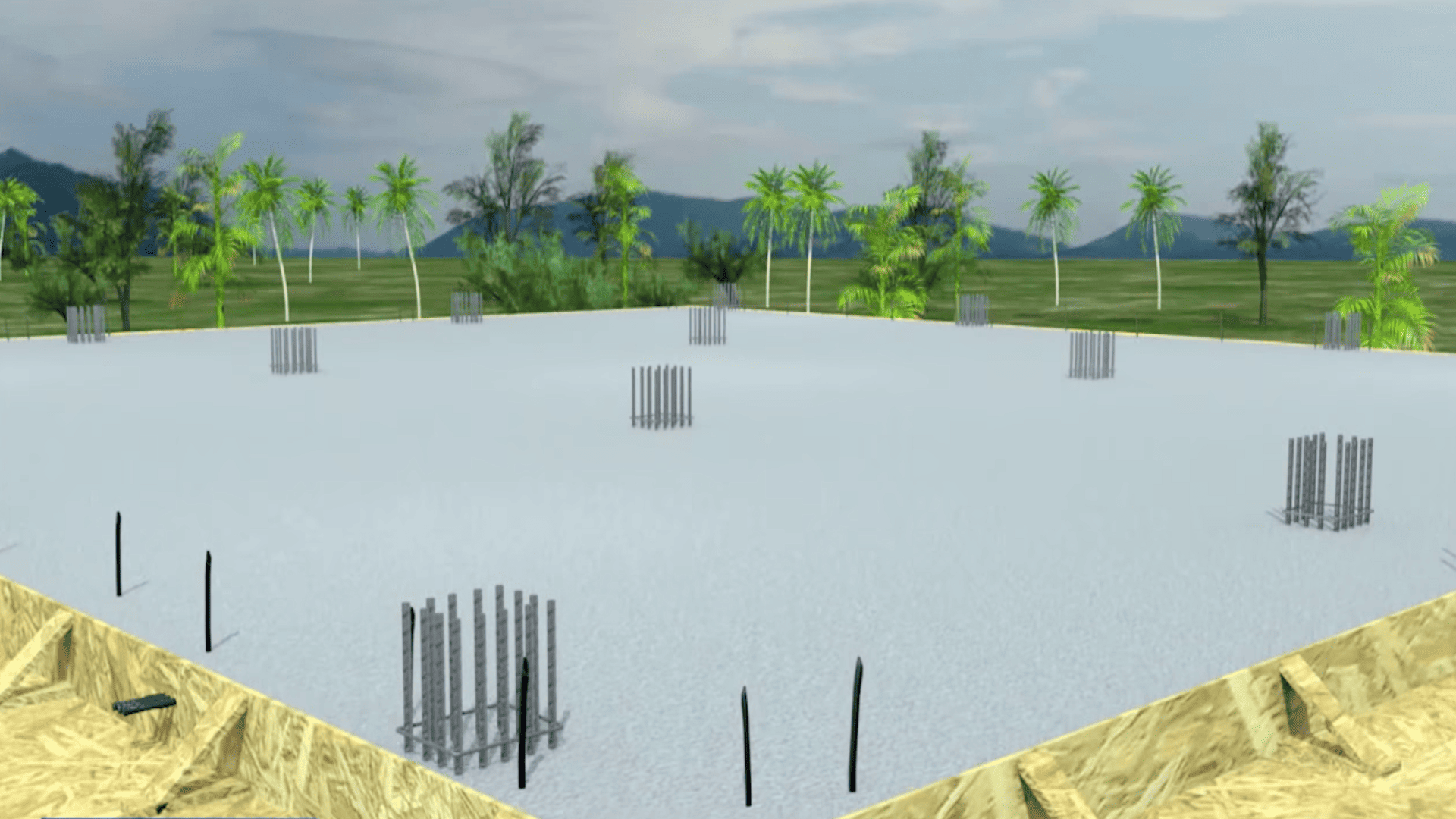

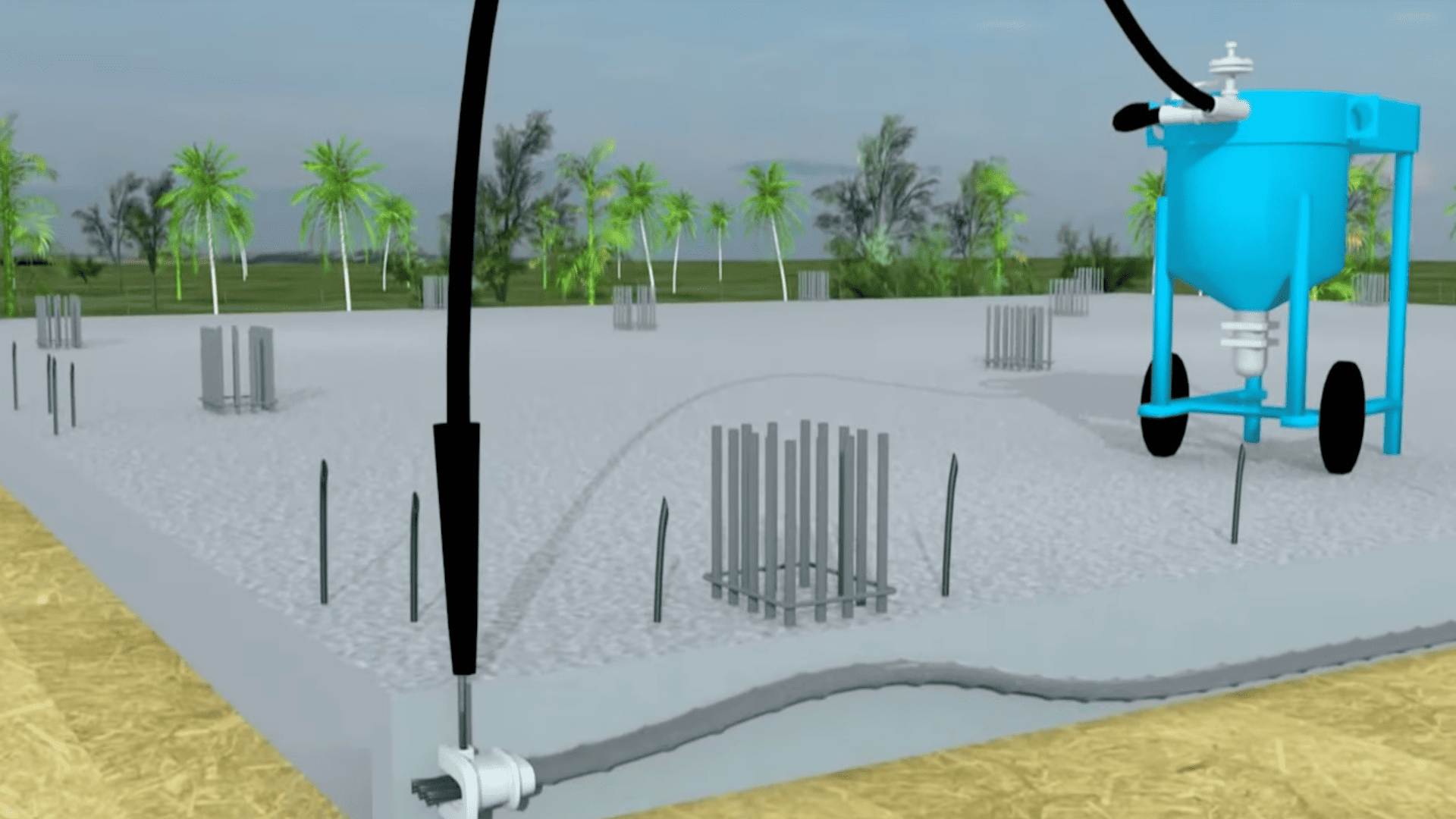

4. Concrete Pouring

Install top reinforcement and any additional structural reinforcement required by design.

Pour concrete throughout the formed area, ensuring complete coverage of all reinforcement and tendons while maintaining specified thickness and quality standards.

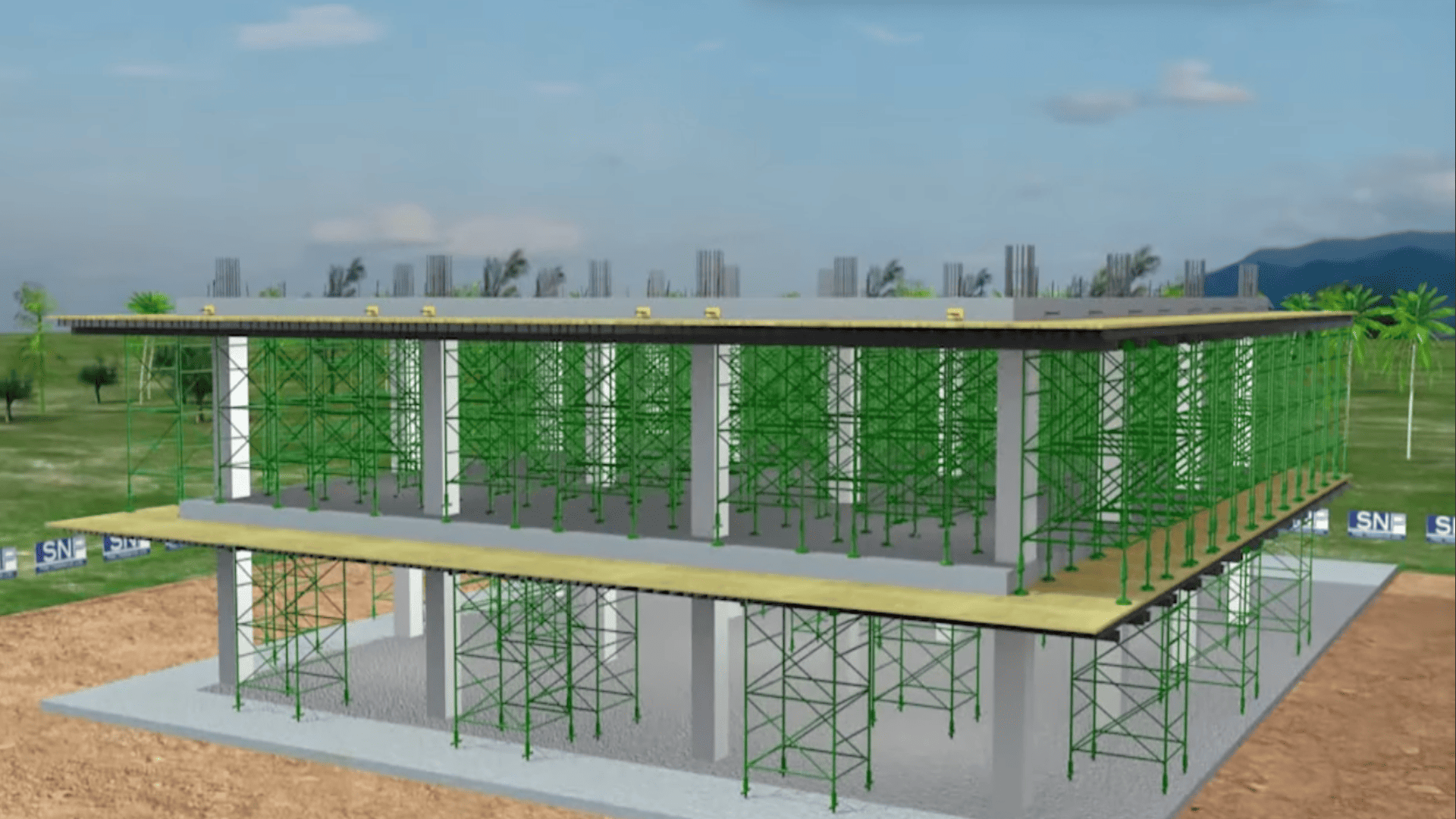

5. Form Removal

Remove side formwork once concrete gains sufficient strength, followed by bottom formwork removal after concrete achieves adequate strength to support its own weight and intended loads without temporary support.

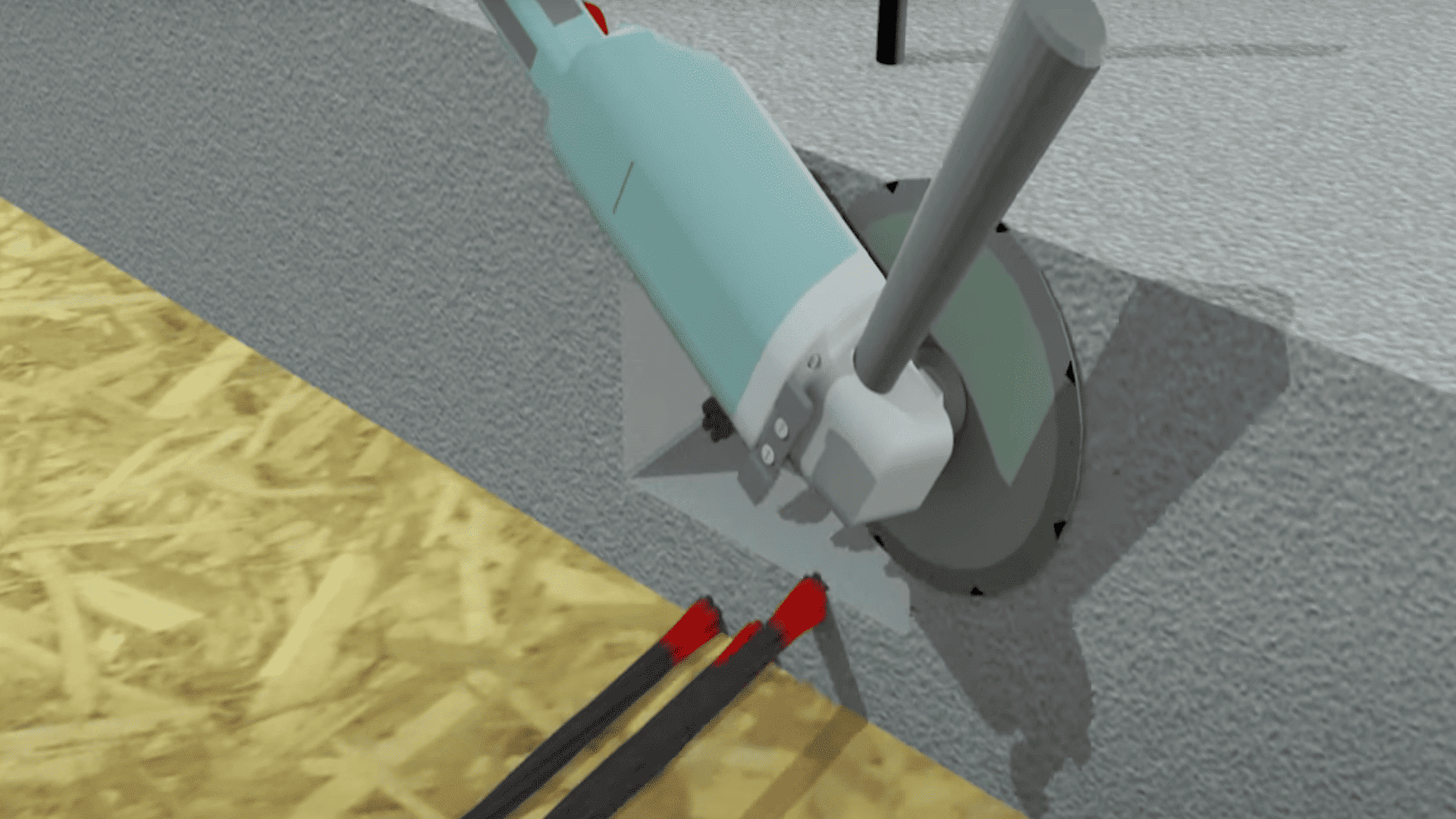

6. Tensioning

Insert blocking elements and connection details, then apply tension to cables using hydraulic jacks while measuring cable elongation.

Cut excess cable length after achieving proper stress levels according to design requirements.

7. Grouting and Protection

Fill anchor sockets with mortar for protection, bleed air from tendon ducts for cleaning, then inject grout into ducts to provide permanent corrosion protection for cables and ensure long-term structural integrity.

8. Final Cleanup

Remove all scaffolds and temporary supporting structures once the slab achieves full design strength and can independently support all intended loads and construction activities.

Video Tutorial

I’d like to give credit to SNP POST TENSION for their informative video, as a reference for this guide.

Advantages and Disadvantages of Post-Tension Slabs

Understanding both the advantages and limitations helps determine when these systems provide the best value for specific construction projects.

| Advantages | Disadvantages |

|---|---|

| Longer spans (up to 40+ feet) with thinner slabs | Higher initial costs, 25-40% more than traditional slabs |

| Reduced cracking from compression force | Complex installation requiring specialized contractors |

| 15-20% less concrete and steel reinforcement needed | Limited modification flexibility once tensioned |

| 20-30% faster construction timeline | Specialized maintenance and regular inspections are required |

| Better seismic performance in earthquake zones | Potential cable failure from corrosion or improper tensioning |

| Design flexibility with fewer support columns | Repair costs are significantly higher than traditional slabs |

| Ideal for poor soil conditions and expansive soils | Consequences of failure can cause sudden structural problems |

| Long-term material savings justify higher investment | Not suitable for simple projects with standard spans |

Post-Tension Slab Cost Per Square Foot

Post-tension slab costs vary significantly based on project complexity and location. Residential projects typically cost $6-11 per square foot, while commercial projects range from $12-25 per square foot due to more complex designs and heavier load requirements.

Cost Comparison Table

| Project Type | Post-Tension Cost | Traditional Cost | Premium |

|---|---|---|---|

| Residential | $6-11 per sq ft | $4-8 per sq ft | 25-40% |

| Commercial | $12-25 per sq ft | $8-15 per sq ft | 30-50% |

| Industrial/Heavy-duty | $20-30 per sq ft | $12-18 per sq ft | 40-60% |

The cost breakdown includes materials (40-50%), labor (35-40%), and equipment (10-15%). While post tension slabs have higher upfront costs, they offer the most value for buildings with spans over 25 feet, projects requiring minimal column support, and structures on challenging soil conditions.

The higher initial investment often pays off through reduced material usage, faster construction, and lower long-term maintenance costs.

The Bottom Line

Post tension slabs offer a modern solution for construction challenges that traditional concrete cannot address effectively. From longer spans and thinner designs to better crack resistance and faster installation, post tension concrete delivers measurable benefits for the right applications.

The decision between post tension and traditional slabs depends on project requirements, budget constraints, and long-term goals.

While initial costs are higher, the material savings, construction speed, and structural performance often justify the investment for commercial buildings, residential projects, and challenging site conditions.

Success with post tension concrete requires working with experienced contractors who understand the specialized installation and tensioning processes.

Have experience with post tension slabs? Share your insights or questions in the comments below—we’d love to hear from you.